Waste management has become a hot topic in a world where managing resources is crucial to the future of the planet. In fact, earlier this year the scientific community warned that the Earth was heading to ‘the point of no return’ unless immediate action to reduce harmful emissions is taken. In this political environment reuse is more important than ever.

Affald Plus in Denmark is a waste disposal company that treats waste from South and West Zealand regions of Denmark to create a valuable resource. It turns the waste into materials for reuse, like biofuels, copper, paper, and ‘upcycling’ of construction waste.

But there are risks involved in these activities - for example, waste silos can produce flammable gases which could ignite if the temperature gets too high. To manage this risk, Affald Plus turned to SeeSafe, a leading Danish security provider – and SeeSafe used Hikvision products to build the solution, including thermal cameras and a decoder managing a video wall for the control centre.

But there are risks involved in these activities - for example, waste silos can produce flammable gases which could ignite if the temperature gets too high. To manage this risk, Affald Plus turned to SeeSafe, a leading Danish security provider – and SeeSafe used Hikvision products to build the solution, including thermal cameras and a decoder managing a video wall for the control centre.

Challenge

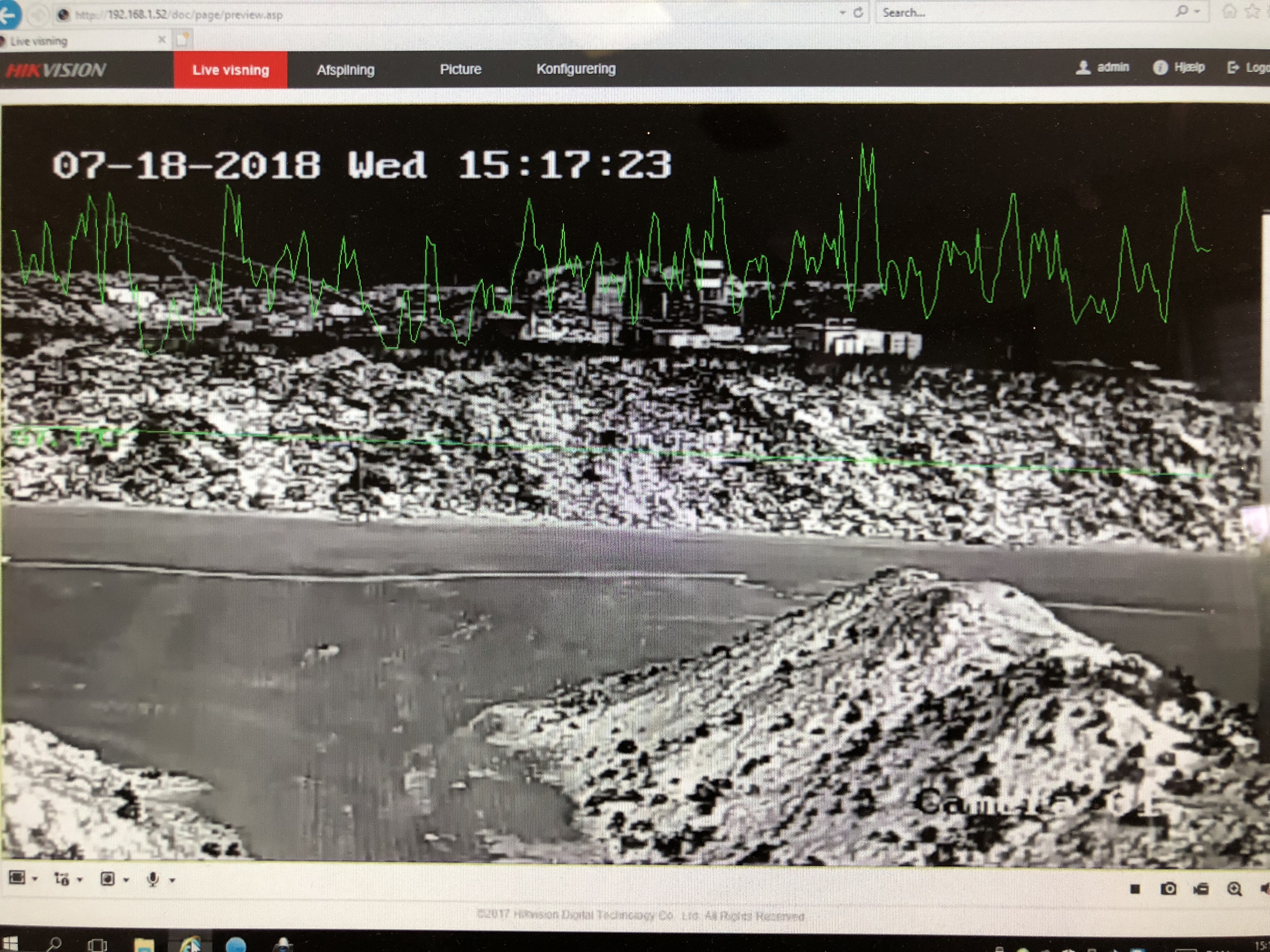

Since many of the silos are unmanned, it’s important that the company has an accurate oversight into what is going on at each of them. Not only do they need to be able to see that they are safe, and that there are no unauthorised persons ‘hanging around’, but also that the temperatures inside are within an acceptable range. Operators are looking out for ‘hotspots’ – areas where the temperature has risen to a level where they need to carefully monitor them, or act. Hotspots are static, but if they move, then it’s likely that there is actually a fire - the nature of flames is much more random, moving around.

Since all of the silos are monitored for a central security office, it was also important to bring in all of the information to the same place and make it easy to see. In order to make swift decisions, the data needs to be clear, accessible and current. In past, this task was very time consuming, with security personnel completing two rounds of the whole plant every day. This also meant that they could not react as quickly to any potential issues.

Solution

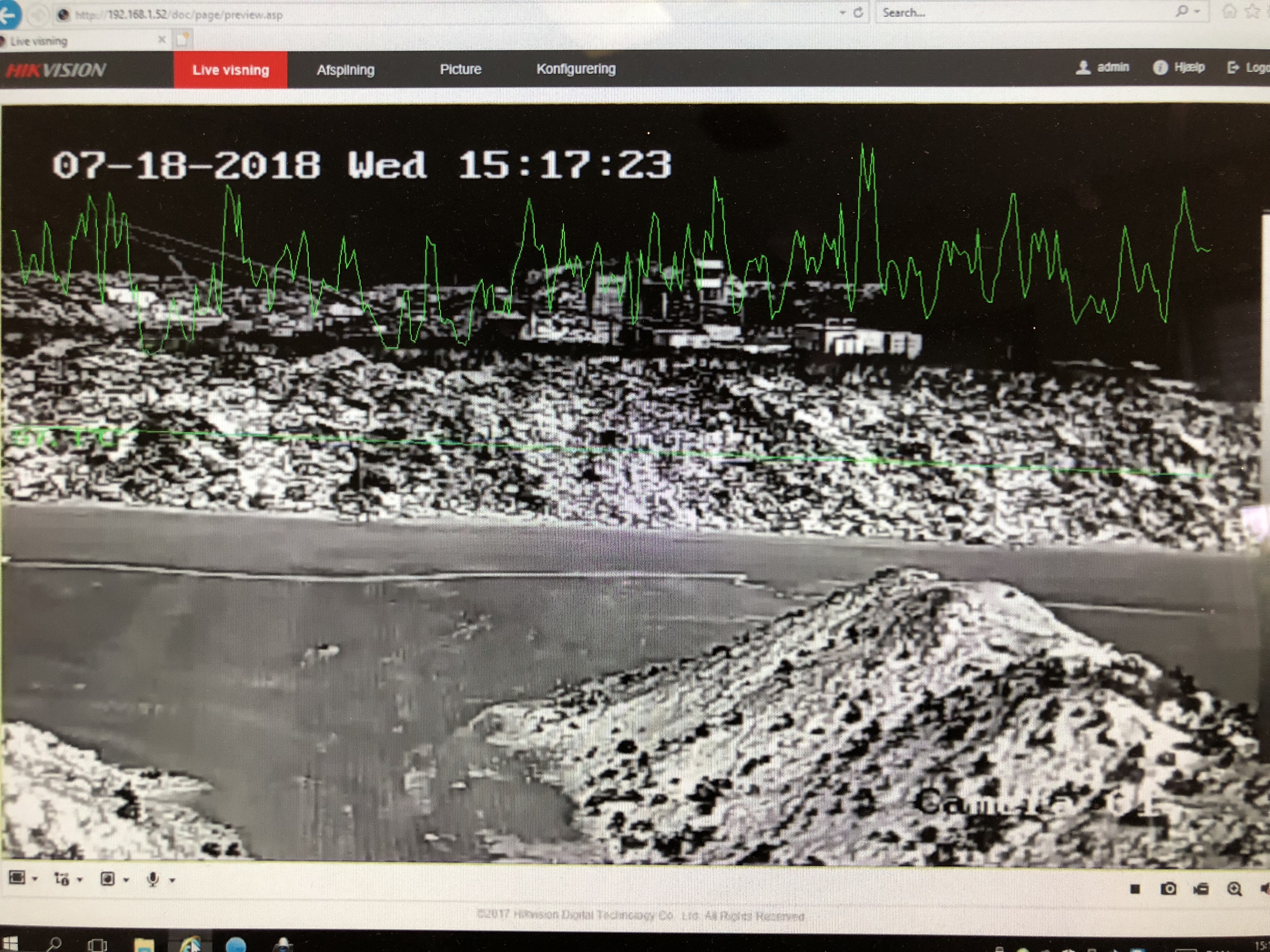

The complete solution took the form of a mix of Turbo HD and IP cameras, DVR and encoders. But the hero products were several thermal network bullet cameras (DS-2TD2136-10) and a decoder device (DS-6910UDI) that managed a video wall in the central security office.

The complete solution took the form of a mix of Turbo HD and IP cameras, DVR and encoders. But the hero products were several thermal network bullet cameras (DS-2TD2136-10) and a decoder device (DS-6910UDI) that managed a video wall in the central security office.

The thermal cameras were chosen specifically for their ability to detect a potential fire through temperature measurement. They can measure temperature between -20°C to 150°C, with an accuracy of ±8°C. Each camera can support 10 fire points, and when the temperatures reach a predefined level at one of them, an alarm is sent directly to the control centre.

Here all the information from the cameras is combined, so operators can easily see what and where the risk is and act accordingly. The decoder displays the decoded video stream on the video wall by directly linking the cameras in the solution. It also allows the video wall to display temperature measurements, dynamic fire source detection and VCA information in live view and playback.

With thermal cameras constantly on the lookout for rising temperatures and a video wall to make it easy to see the status of the silos, Affald Plus Operating Manager Jeppe Steen Elvang can rest easier. He says: “With these new thermal cameras we can constantly monitor the heat of the large amount of waste we have in silos. We get alarms when it approaches dangerous temperatures. We can now follow all processes effectively and monitor critical sites in the plant and at our unmanned locations.”

With thermal cameras constantly on the lookout for rising temperatures and a video wall to make it easy to see the status of the silos, Affald Plus Operating Manager Jeppe Steen Elvang can rest easier. He says: “With these new thermal cameras we can constantly monitor the heat of the large amount of waste we have in silos. We get alarms when it approaches dangerous temperatures. We can now follow all processes effectively and monitor critical sites in the plant and at our unmanned locations.”

With the help of SeeSafe and Hikvision cameras, Affald Plus can contribute to recycling targets in a safe and sustainable way. And, hopefully, with the continuing efforts of companies and projects like this, the point of no return predicted by scientists will be pushed further away.

Find out about the thermal cameras.

Find out about the decoder.

New Products

New Products But there are risks involved in these activities - for example, waste silos can produce flammable gases which could ignite if the temperature gets too high. To manage this risk, Affald Plus turned to SeeSafe, a leading Danish security provider – and SeeSafe used Hikvision products to build the solution, including thermal cameras and a decoder managing a video wall for the control centre.

But there are risks involved in these activities - for example, waste silos can produce flammable gases which could ignite if the temperature gets too high. To manage this risk, Affald Plus turned to SeeSafe, a leading Danish security provider – and SeeSafe used Hikvision products to build the solution, including thermal cameras and a decoder managing a video wall for the control centre. The complete solution took the form of a mix of Turbo HD and IP cameras, DVR and encoders. But the hero products were several thermal network bullet cameras (DS-2TD2136-10) and a decoder device (DS-6910UDI) that managed a video wall in the central security office.

The complete solution took the form of a mix of Turbo HD and IP cameras, DVR and encoders. But the hero products were several thermal network bullet cameras (DS-2TD2136-10) and a decoder device (DS-6910UDI) that managed a video wall in the central security office. With thermal cameras constantly on the lookout for rising temperatures and a video wall to make it easy to see the status of the silos, Affald Plus Operating Manager Jeppe Steen Elvang can rest easier. He says: “With these new thermal cameras we can constantly monitor the heat of the large amount of waste we have in silos. We get alarms when it approaches dangerous temperatures. We can now follow all processes effectively and monitor critical sites in the plant and at our unmanned locations.”

With thermal cameras constantly on the lookout for rising temperatures and a video wall to make it easy to see the status of the silos, Affald Plus Operating Manager Jeppe Steen Elvang can rest easier. He says: “With these new thermal cameras we can constantly monitor the heat of the large amount of waste we have in silos. We get alarms when it approaches dangerous temperatures. We can now follow all processes effectively and monitor critical sites in the plant and at our unmanned locations.”