Dock management intelligent solutions

Loading and unloading cargo at the docks of fulfillment or distribution centers are key steps in the logistics process. Traditional logistics companies often lack sufficient video recordings, especially when there is damage or loss of goods. And it might be stressful for them to track the status of each dock, due to heavy workloads and the large numbers of docks to be managed. Therefore, optimizing dock operations and management is of paramount importance for enhancing efficiency for any growing business.

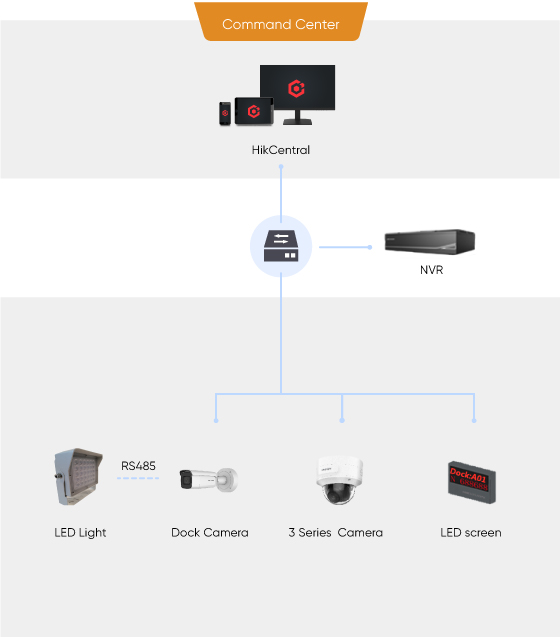

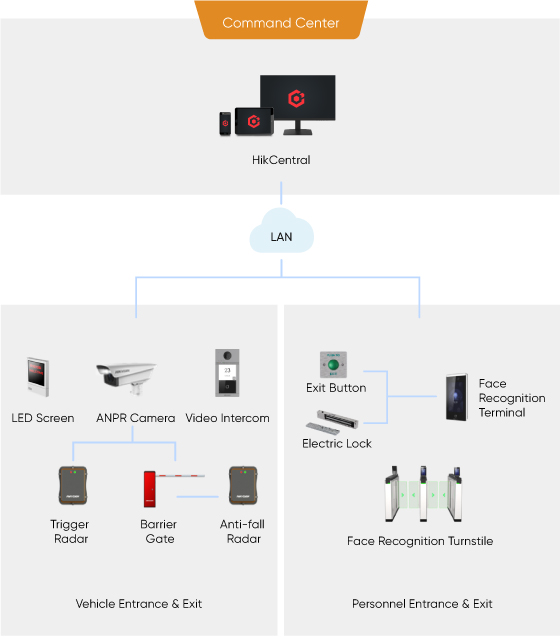

All of these problems can be conveniently solved using the Hikvision Dock Management Solution. It’s powered by AI technologies and products with tailored algorithms, such as the intelligent dock camera. ANPR technology, dock status, entry & exit detection, and more, all come together in this solution to help logistics operators create more efficient loading & unloading processes as well as improve vehicle and resource allocations, enhancing overall efficiency. Read on to learn how Hikvision’s dock management solution can help your logistics operation today.

Key Technologies

Dock Camera – High-end intelligent camera with tailored algorithms:

Enhance efficiency and increase visibility for dock management

Download

You may also be interested in

Augmented automation greatly saves time and improves experience

You may also be interested in

You may also be interested in

Hikvision.com uses strictly necessary cookies and related technologies to enable the website to function. With your consent, we would also like to use cookies to observe and analyse traffic levels and other metrics / show you targeted advertising / show you advertising on the basis of your location / tailor our website's content. For more information on cookie practices please refer to our cookie policy.